Diamond Core Drill Bit General Drilling Techniques

Diamond drill bits are specifically designed for use on very hard materials as shown in the materials section. The extremely hard nature of the materials requires that the diamond drill bits be used with proper drilling techniques. Improper use can overheat and damage the drill bit and may also cause heat fractures and material breakage.

The three primary drilling techniques of Drill Speed, Drill Pressure and Lubrication, must work together to allow the drill bit to function without overheating from friction due to the extremely hard material. When used properly, the diamond drill bit should NEVER be HOT. The drill bit should never be more than warm, to the touch. If a bit becomes hot, it is an indication of inadequate lubrication, too fast a drill speed or too much pressure for the specific material being drilled.

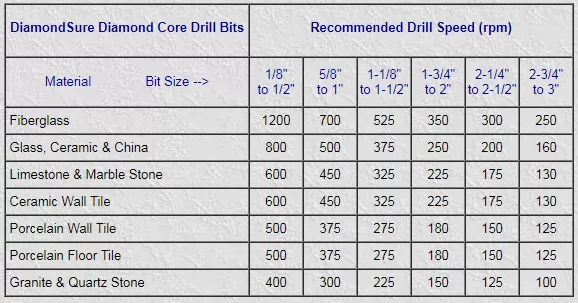

The following table shows recommended drill speeds. Drill speeds considerably in excess of these speeds will quickly burn up the diamond bits. Proper drill speeds, low drill pressure and adequate use of water for lubrication will extend drill bit life.

(Not for use on Concrete or Masonry, or with Hammer Drills)

SPEED KILLS: Reduced drill speeds, low drill pressure and plentiful use of water lubrication will extend drill bit life considerably.

Since all materials vary in hardness and abrasiveness, it is impossible to determine exact drill speeds for all possible materials. Additionally, as discussed below, lubrication and drill pressure must also be considered when determining the proper drill speed. A faster drill speed or increased pressure may reduce the cutting time slightly, but it will also increase the friction significantly and heat up the bit, reducing the bit life considerably and increasing the risk of heat fractures and material breakage.

If used properly, a diamond drill bit should never be more than warm when touched after use. If a drill bit develops yellow, brown, blue or black 'burn marks' around the tip, it is an indication of extreme heat and that the drill speed being used is too fast, the amount of pressure on the drill is too great, or the amount of water lubrication is completely inadequate.

Diamond Drill Bit Lubrication

Water or coolant must always be used to cool and lubricate the tip. The lubrication reduces heat build-up, prolonging drill bit life and helps avoid heat fractures in the material. Water is most often used as the lubricant, since it works very well and has no cost. Oil based lubricants do not work well on diamond drill bits.

Good lubrication is critical. Minimal lubrication will keep the bit from burning up, but very good lubrication techniques will extend bit life by a factor of 5 or even 10.

When drilling in fiberglass, a diamond drill bit can be used dry or with a very small amount of water. When drilling in glass or ceramic, soft ceramic tile and porcelain, if properly lubricated, the dust from the cut should dissipate into the water. The drill bit contact with the surface should always be wet and the drill bit tip should never be hot. If the tip is ever more than just warm, it is generally an indication of too little lubrication (or possibly too much speed or pressure).

When drilling in hard, abrasive materials such as limestone, sandstone, hard ceramic and porcelain tiles, marble or granite, it is critical to have lots of lubrication. With these hard materials, it is common to drill under water or to have a small amount of water constantly running over the drill bit and bore hole. In either case, the "pumping" technique described below is needed to assure water reaches the very tip of the bit.

This discussion is presented only as a guide. It is almost impossible to have 'too much' lubrication and the only down side risk is the mess from water being thrown off by the bit. However, 'too little' lubrication will cause many problems.

Drill Bit Lubrication Tips & Techniques

Various kinds of very specialized industrial water feed equipment are available for industrial production type work. But, when drilling with diamond bits, the primary concern is merely getting enough water lubrication on the cutting edge of the bit, no mater what method is used.

However, all lubrication methods are not equal. Since good lubrication extends drill bit life considerably, we rated the various methods to help people understand the differences between the various methods. As a rule of thumb, the relative rating also gives a general indication of the relative drill bit life under various lubrication methods. For example, the basic clay dam lubrication method (4 rating) should provide a drill bit life of approximately twice that of using a squirt bottle (2 rating).

| Drill Bit | Rating |

| Lubrication Method | (1 poor - 10 good) |

| Squirt Bottle | 2 |

| Hose | 3 |

| Clay Dam | 4 |

| Under Water | 4 |

| Squirt Bottle w/pumping action | 6 |

| Clay Dam w/pumping action | 10 |

| Under Water w/pumping action | 10 |

| Water Feed | 10 |

Hose or Water Drip Method: The most basic method is to use a small hose that runs water onto the surface near the hole and down into the bore hole. To provide lubrication on a horizontal surface, one trick is to place a plastic jug or bottle with a small hole near the bottom of it, next to the drill hole. The water leaks out of the bottle and provides continuous lubrication as you drill. To allow lubrication to reach the drill tip, it is very important to use a "pumping" technique described below. Without the pumping technique, the water will not reach the very tip of the drill bit.

Clay Dam: Another excellent lubrication technique is to build a "dam" around the drill hole using a small amount of modeling clay or a similar material. This method can be very effective, especially if the water extends above the side tip lubrication hole to allow water to flow into the bit providing good interior lubrication. "Pumping" the drill is also very important to increase the lubrication at the tip. Without the pumping technique, the water will not reach the very tip of the drill bit. The clay can be used many times if it is stored in a plastic zip-lock style bag to keep it from drying out.

Pan Drilling: For low volume repetitive work, it is also possible to place the material into a pan or plastic tub (place a thin plastic board underneath so you don't drill into the pan) and fill the pan with water so that it covers the surface of the material being drilled. The water should cover the side lubrication hole on the tip of the diamond drill bit. To allow lubrication to reach the drill tip, it is very important to use a "pumping" technique described below. Without the pumping technique, the water will not reach the very tip of the drill bit even though the bit is under water.

Spray Bottle: When drilling on vertical surfaces, about the only way to apply water is to use some type of hose. If that is not possible, a marginally effective solution is to have someone constantly "squirting" water into the bore hole using a squirt bottle. Squirting water will usually keep the bit from burning up, but unless a pumping action is used, the water will not reach the very tip of the drill.

Pumping Technique: No matter what lubrication method is used, a periodic "pumping" action will significantly improve lubrication at the drill tip. Because of the pressure on the drill tip, water has trouble reaching the very tip of the drill bit. A "pumping" technique allows lubrication to reach the very tip. While drilling, merely raise the drill up and down a fraction of an inch once in a while as you drill (maybe every 15 to 20 seconds or so). This assures that water enters the drill tip area completely and fully lubricates the very tip. Pumping the drill improves lubrication at the tip and will improve drill bit life considerably.

To view more diamond tools and machinery for making diamond tools, welcome to contact with Boreway sales team,24hours in service!

![$curr_position[0]['banner'][0]->alt](https://v.zawl.cn/907/upload/image/20211101/214402-82.webp)